XRF, OES & LIBS | Material Analysis

Unlock True Elemental Insight — Anywhere, Anytime

From the lab to the field, get unmatched material analysis with the industry’s best: Belec OES for ultra-precise alloy chemistry, Niton XRF for fast, non-destructive screening, and the Niton Apollo LIBS for on-the-spot carbon and light element detection. Whether you’re verifying materials, ensuring compliance, or preventing critical failures — these technologies deliver the confidence you need, exactly where you need it.

Supported Industries:

Positive Material Identification (PMI) | Scrap Metal Recycling | Environmental | Precious Metals | Mining & Exploration | Consumer Goods | Plastics | Pharmaceutical

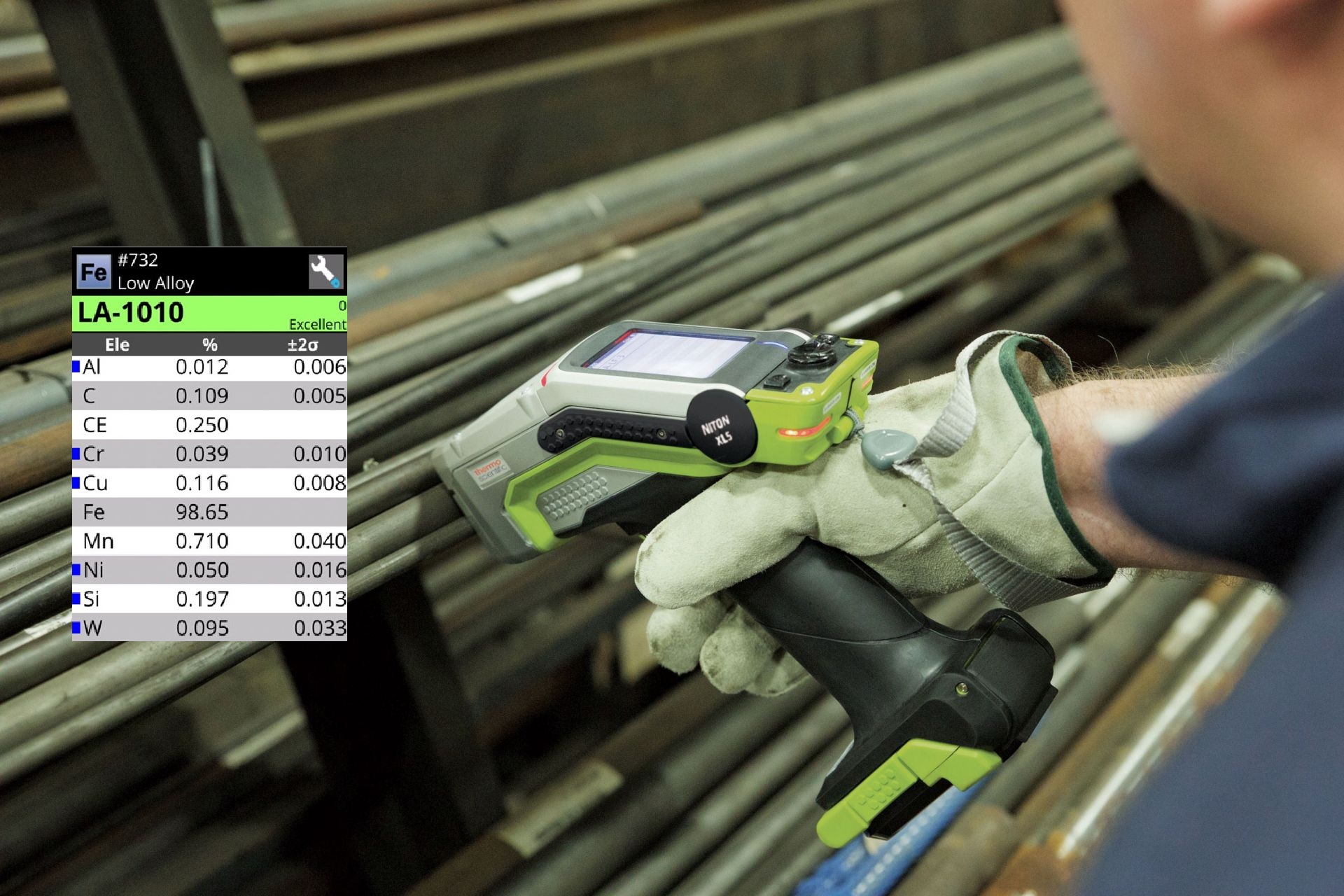

What is XRF | Niton XL5 Plus

The world’s smallest handheld XRF analyzer

XRF, or X-Ray Fluorescence, is a non-destructive analytical technique employed to determine the elemental composition of materials. The Thermo Scientific™ Niton™ XL5 Plus utilizes this technology to provide rapid, on-site elemental analysis.

The Niton™ XL5 Plus stands out as the lightest and smallest handheld XRF analyzer available, weighing just 2.8 lbs (1.3 kg). Despite its compact size, it houses a powerful 5W X-Ray tube and an advanced silicon drift detector with a graphene window, ensuring low detection limits for both heavy and light elements like magnesium, aluminum, and silicon .

Designed for versatility, the XL5 Plus features a tilting color touchscreen, hot-swappable batteries, and integrated micro and macro cameras for precise targeting and documentation. Its rugged, IP54-rated design makes it suitable for various industrial environments, including oil and gas, metal fabrication, mining, and environmental assessment .

With its advanced capabilities, the Niton™ XL5 Plus enables users to perform tasks such as positive material identification (PMI), alloy verification, coating thickness measurements, and hazardous substance screening efficiently and accurately.

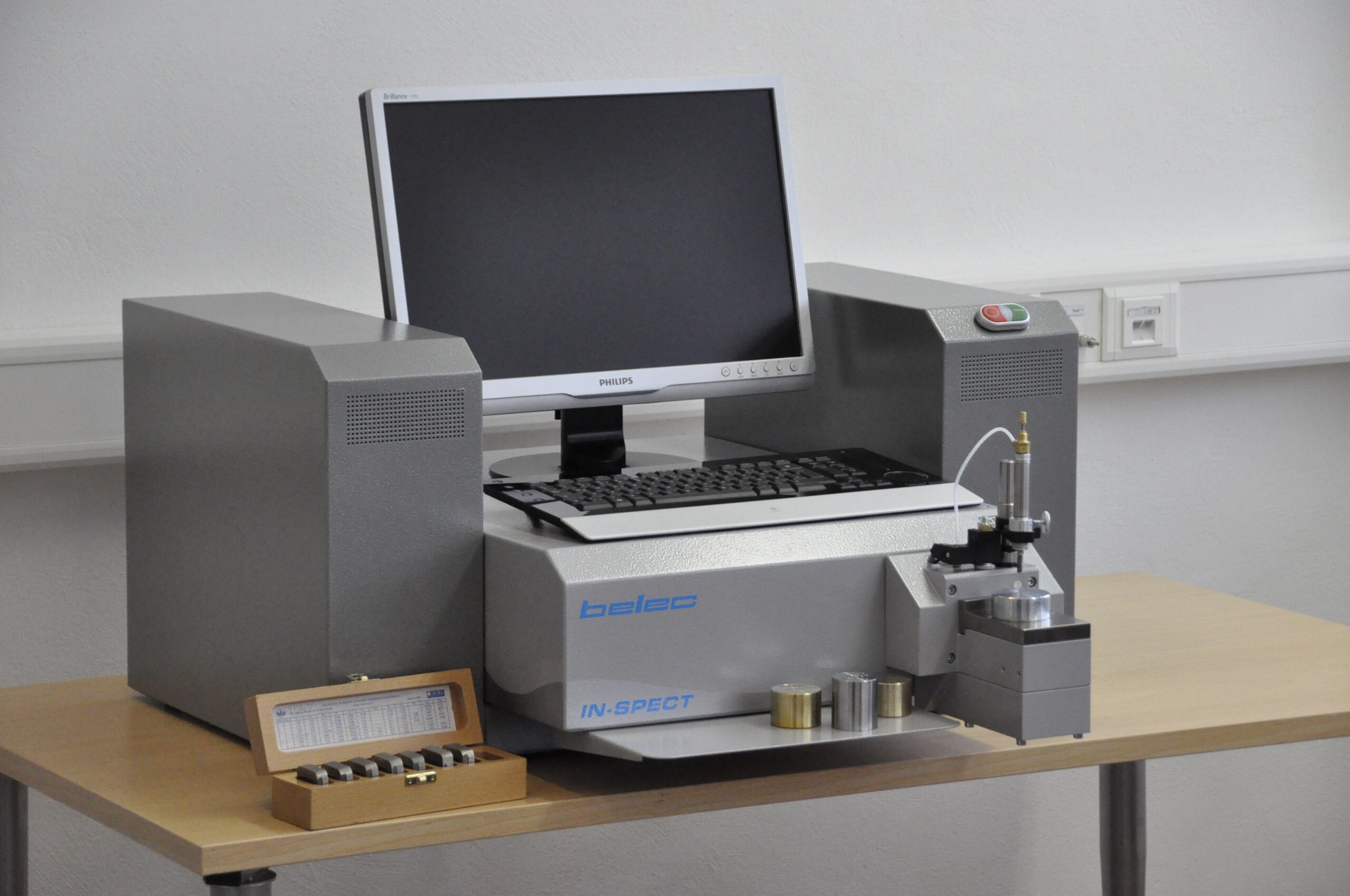

What is OES | BELEC IN-SPECT

The Lab on the desk

Optical Emission Spectrometry (OES) is an analytical technique that determines the elemental composition of metallic samples by measuring the light emitted from a plasma generated on the sample’s surface. The Belec IN-SPECT is a stationary OES analyzer designed for high-precision metal analysis in various industrial applications.

The IN-SPECT features a unique dual-spectrometer optical system, providing a broad wavelength range of 170–700 nm. This design ensures accurate detection of a wide array of elements, including trace elements, with low detection limits. Its open sparking stand accommodates larger or irregularly shaped samples, enhancing versatility in sample analysis.

Equipped with the latest 7th Generation Spectrometer Optic System (7GSO), the IN-SPECT delivers rapid analysis speeds and high accuracy. The user-friendly Belec Win 21 software facilitates efficient operation and data evaluation. With its compact design and robust construction, the IN-SPECT is ideal for applications in foundries, recycling industries, goods receiving, and quality control in production environments.

What is LIBS | Niton Apollo LIBS

Carbon Equivalence & Elemental Analysis

LIBS, or Laser-Induced Breakdown Spectroscopy, is an analytical technique that utilizes a high-powered laser to ablate a tiny amount of material from a sample, creating a plasma. As the plasma cools, it emits light at wavelengths characteristic of the elements present. The Niton™ Apollo™ employs this technology to deliver rapid, in-field elemental analysis,

particularly excelling in detecting light elements like carbon.

Designed for portability and efficiency, & weighing just 6.4 pounds (2.9 kg), it enables users to perform accurate analyses in challenging environments, such as pipelines and trenches.

Key features include a 1064nm laser, high-purity argon purge for enhanced accuracy, macro and micro cameras for precise targeting, and a tilting, color touchscreen for easy navigation. The device is also WiFi-enabled, allowing for seamless data transfer and real-time decision-making.

With its ability to provide lab-quality results in approximately 10 seconds, the Niton™ Apollo™ is ideal for applications like Positive Material Identification (PMI), alloy composition determination, and carbon equivalency calculations, making it a valuable tool in industries such as oil and gas, metal fabrication, and manufacturing.

Industry Applications

PRECIOUS METALS

OIL & GAS

ENERGY

MANUFACTURING

Industry | Metal | Environmental | Mining

Rapid results & a new caliber of analytical performance. Wider alloy coverage and lower limits of detection, especially for light elements, allow operators to scan a broader range of incoming or installed materials more quickly.