Non-Destructive Testing [NDT/NDI]

Nondestructive testing (NDT) is the process of inspecting, testing, or evaluating materials, components or assemblies for discontinuities, or differences in characteristics without destroying the serviceability of the part or system. In other words, when the inspection or test is completed the part can still be used. Our Level III ASNT certified experts provide support to help you meet your NDT needs.

Professional NDT/NDI Services

Meeting Your Non Destructive Testing Needs

Nondestructive Testing (NDT) is a wide group of analysis techniques used in science and industry to evaluate the properties of a material, component, or system without causing damage. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research.

We provide inspection services for:

- Coating Thickness [NACE & UTT]

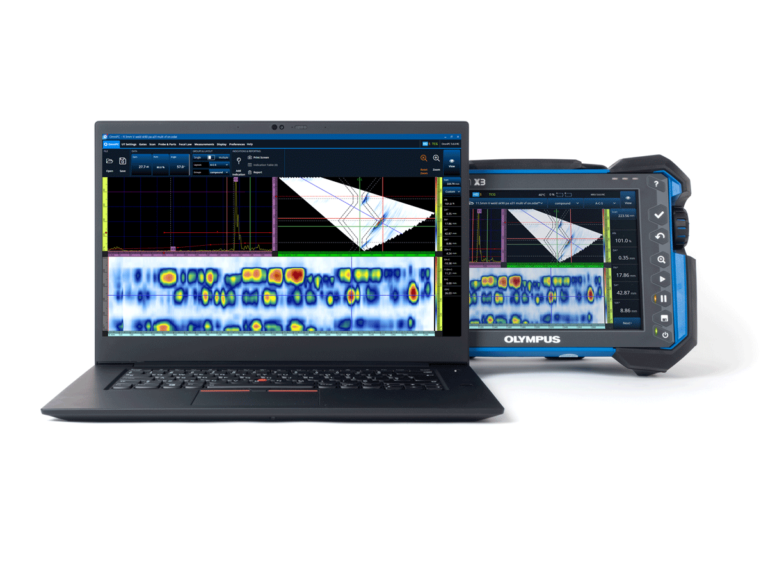

- Ultrasonic Testing [UT | PAUT]- Flaw Detection & Phased Array

- Eddy Current [ECT]

- Radiographic Testing [RT]

- Liquid Penetrant [PT]

- Magnetic Particle Inspections [MPI]

- Infrared Testing [IR]

- Remote Visual Inspection [RVI] – Borescope Inspections [BSI]

NDT is a frequently used tool in aviation, forensic engineering, mechanical engineering, electrical engineering, civil engineering & systems engineering.